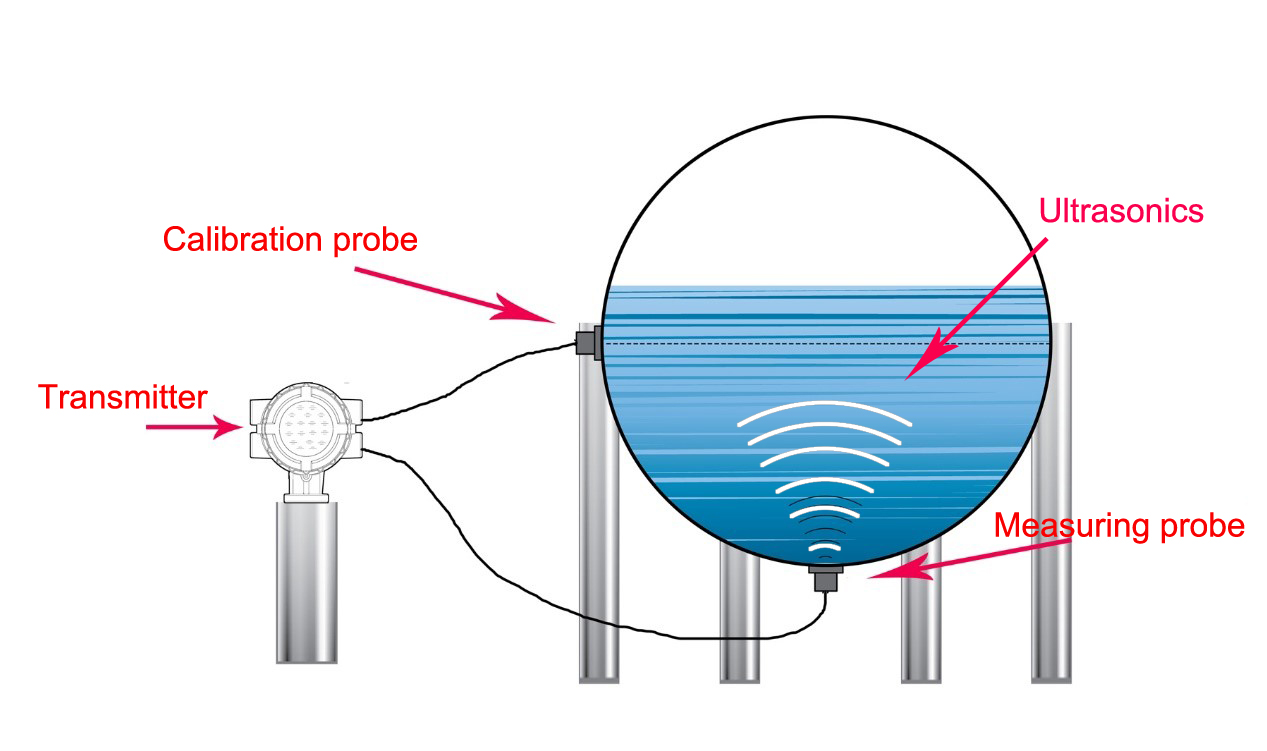

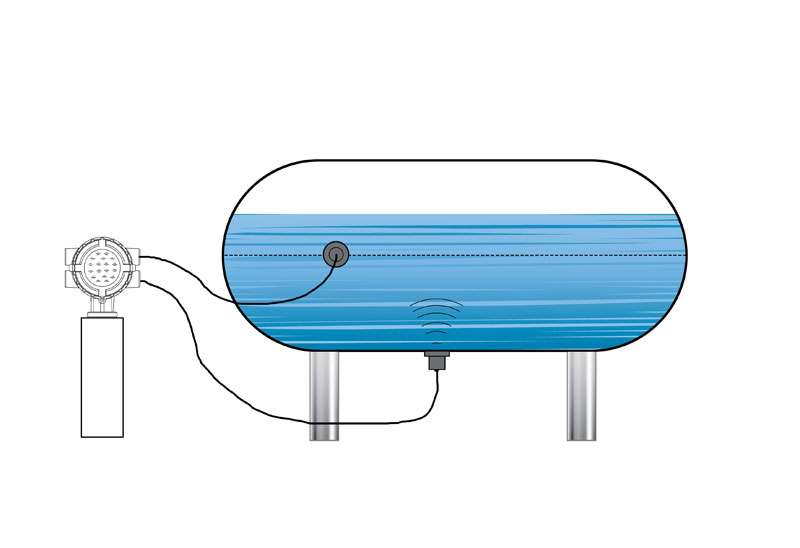

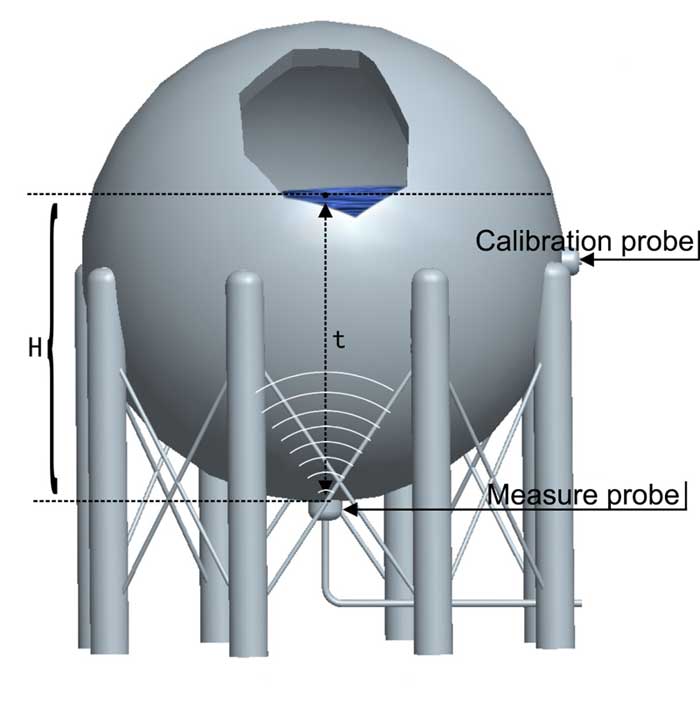

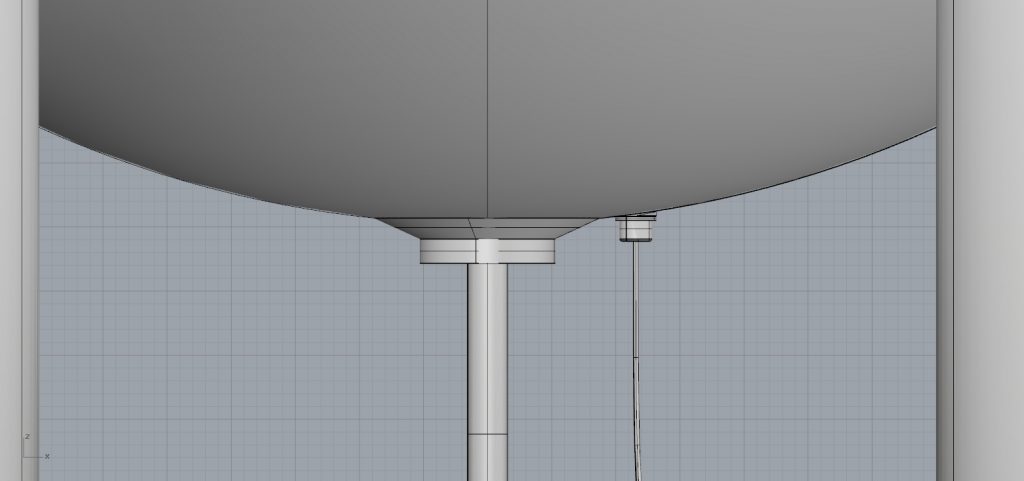

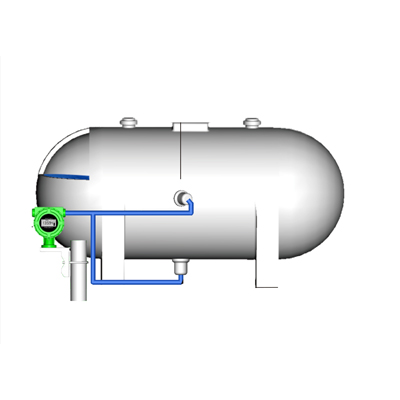

Non-invasive Ultrasonic Level Gauge is also known as Non-contact Level Gauge or Non-invasive Level Gauge. Because it is installed externally at the bottom of the tank, it really achieves a non-contact measurement.

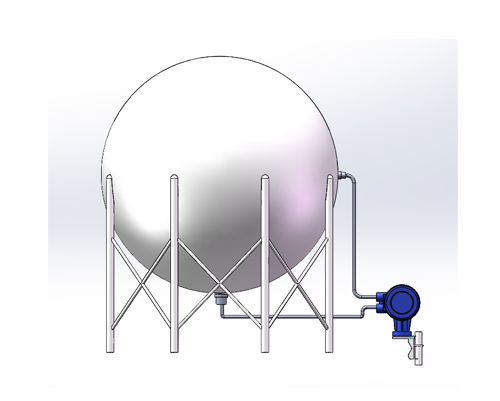

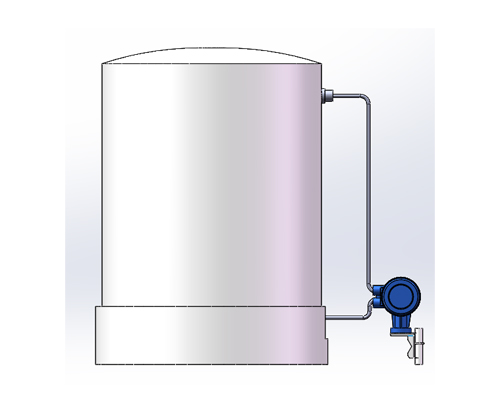

1. Good versatility. It can measure all kinds of tanks, spherical tanks, vertical tanks, horizontal tanks, and other irregular tanks

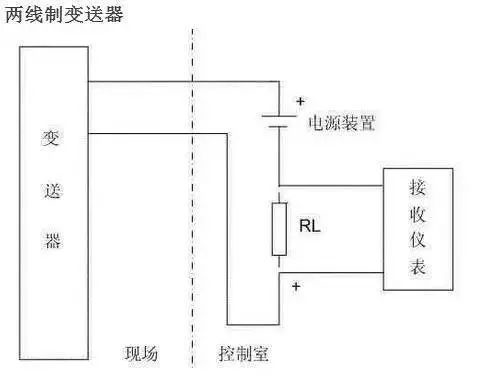

2. Two-wire system. 24V DC power supply, lower power consumption, safer. Reduce wiring costs.

3. The sensor realizes non-contact or non-invasive measurements to improve the probe’s resistance to harsh process conditions.

4. Stm32 microcontroller technology embedded in the application makes precision a more accurate, more intelligent instrument.

5. Easy to install. Large installation space and other auxiliary facilities are not required. It is easy to install, maintain, and use.

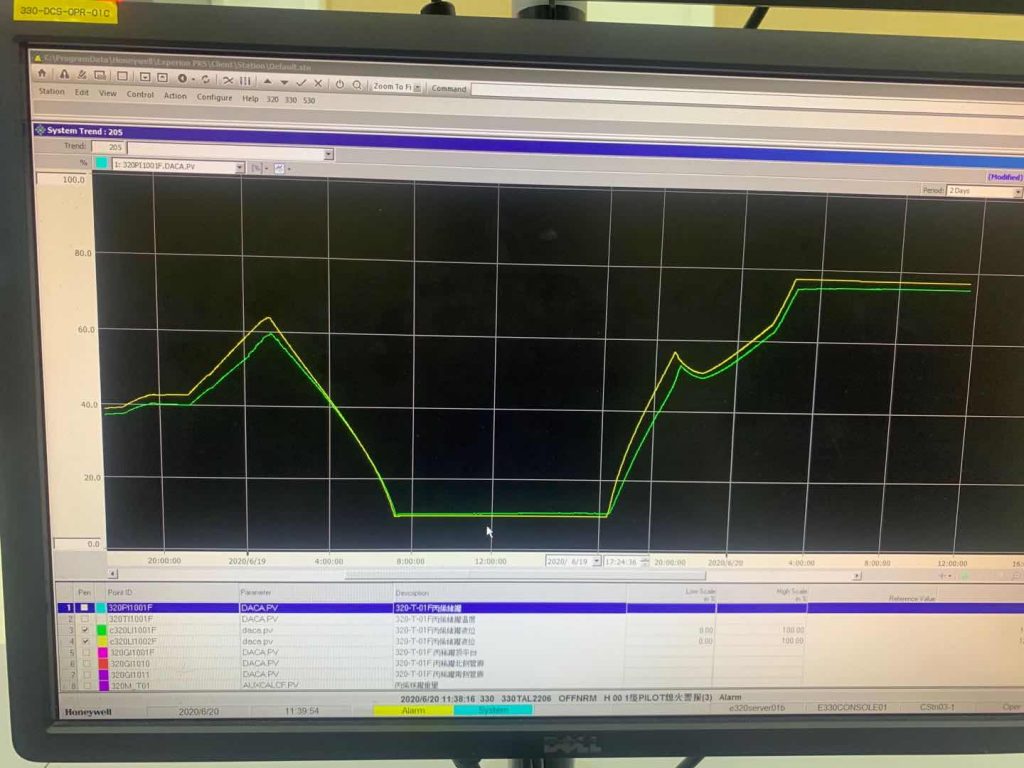

6. It can not only display on site but also send a control signal to connect DCS or SIS system.